|

The original principles of jet milling are simple, the powder

particles are fed into the flat cylindrical milling chamber

tangentially through a venturi system by pressurized process gas.

The particles are accelerated in a spiral movement inside the

milling chamber by a number of nozzles placed around the periphery

of the chamber. The micronizing effect takes place in front of the

spray nozzles by the collision between the slower and the

accelerated particles while the 3 dimensional classification is

based on the particles energy content.

The particle size distribution is controlled by adjusting a wide

set of parameters such an extent that every machine comes already

set up, leaving a very reduced set of parameters to the user, three

of the main ones are Venturi-Ring pressures and feed rate.

PROCESS APPLICATIONS

Pharmaceutical

production Pharmaceutical

production

EV

power batteries EV

power batteries

Metal

powders for additive manufacturing Metal

powders for additive manufacturing

Cosmetic

silky touch and bright powders Cosmetic

silky touch and bright powders

Pesticides

and pigments production Pesticides

and pigments production

Solid

fuels for space rockets (not weapons...) Solid

fuels for space rockets (not weapons...)

Whichever

high value powder... Whichever

high value powder...

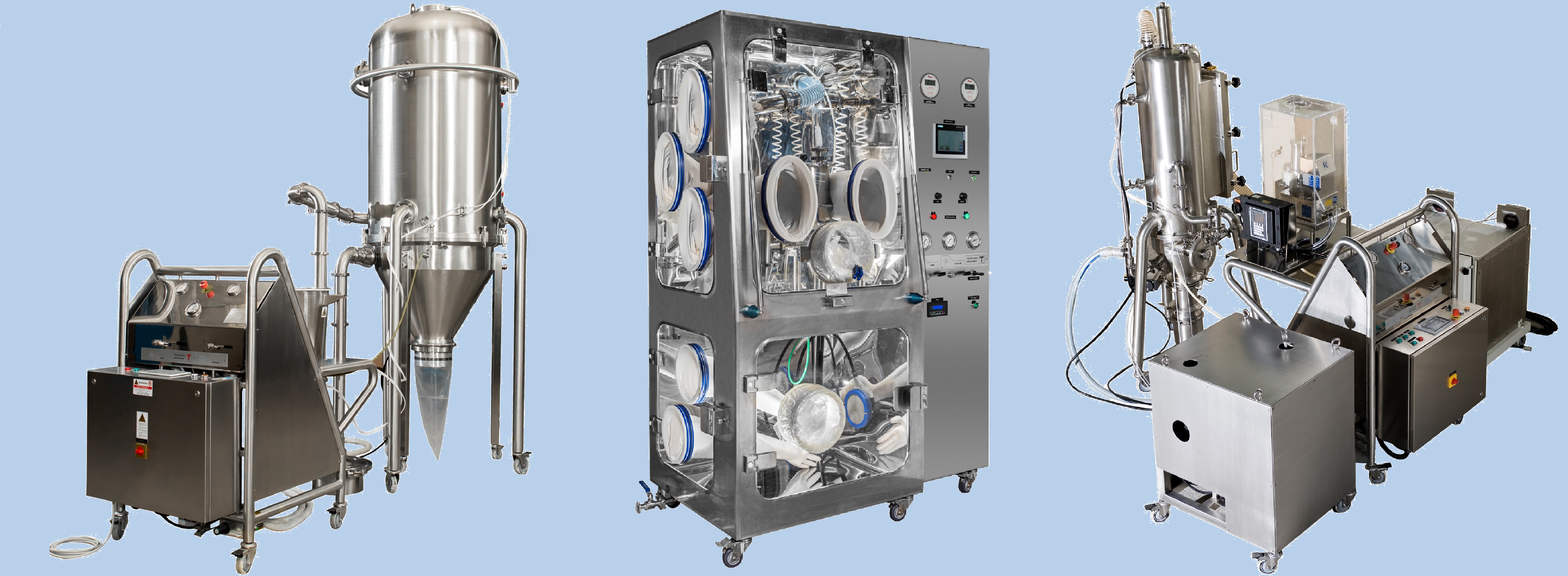

ADVANCED JET MILL SYSTEMS

J-10 designed for

nce J-10 designed for

nce

J-20

J-25 J-30 designed for r&d J-20

J-25 J-30 designed for r&d

J-40

J-50 J-70 designed for pilot or small production J-40

J-50 J-70 designed for pilot or small production

J-100

J-125 J-150 designed for small production J-100

J-125 J-150 designed for small production

J-200

J-300 J-400 designed for medium wide production J-200

J-300 J-400 designed for medium wide production

J-500

J-600 J-750 J-900 designed for huge production J-500

J-600 J-750 J-900 designed for huge production

Please get in contact with us by filling in our "contact us"

form, you will

receive an engineered solution to your micronization process

application.

read more

|